Industrial Applications

Kolina’s industrial Electrocoagulation plants comprise of a four-stage treatment train that compactly combines proven solids separation with patented Electrocoagulation technology in a 40 ft container. The plant contains balance tanks with level sensors that contribute to the full automation of the plant. The combination of technologies integrated in Kolina’s standard 40ft offering allows for:

- A physical separation pre-treatment to remove suspended solids

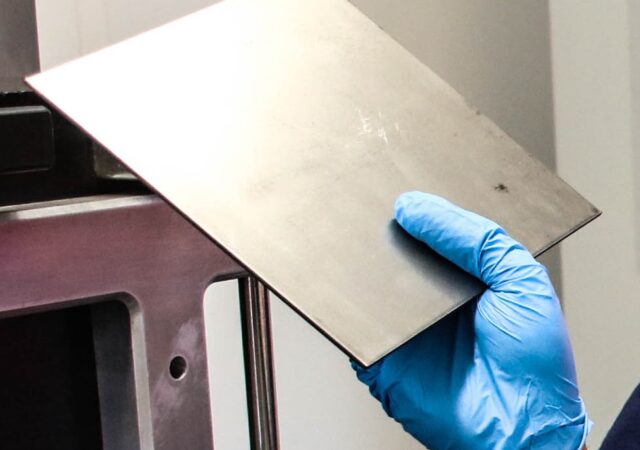

- Electrocoagulation in Kolina’s patented cells to remove dissolved organic, metal, inorganic and complex contaminants

- A non-chemical DAF to provide the necessary retention time for separation and settlement of coagulated and flocculated contaminants

- Final effluent polishing multi-media filtration system with automated backwash to ensure effluent discharge to sub 25 microns

Let us show you what you can find within our EC wastewater unit and how its compact footprint can help address your water treatment challenges.