Award winning ethnic food producer achieves environmental targets and reduces treatment costs

A Manchester based, family owned ethnic food producer was regularly exceeding discharge consent limits and absorbing very high operating costs.

On site space was at a premium as was the operational resource needed to manage any new effluent treatment system.

The required solution must significantly improve the company’s environmental performance and at the same time, reduce costs (both operational and mogden formula).

To collect a suite of technical sampling, and following full technical analysis, Kolina installed and commissioned their proprietary containerised treatment solution which, was able to meet the required reduction in loadings, reduce operational input thanks to full automation of the control panel and Electrocoagulation cells, and, they were able to site the plant within the factory grounds. Following the client’s engineering team completing civil works, Kolina was able to fully commission the new effluent treatment plant in less than 2 weeks.

The site now operates within its set discharge consent limits and is exceeding the company’s environmental and sustainability targets. An average COD reduction of 82% and TSS reduction of 89% resulted in a overall trade effluent discharge saving of 74%.

System commissioned and operational in 2 weeks

Discharge requirements achieved and consent compliant

“We now achieve consent levels and enjoy a 74% reduction in our effluent discharge cost, all thanks to Kolina's Electrocoagulation technology.”

Managing Director

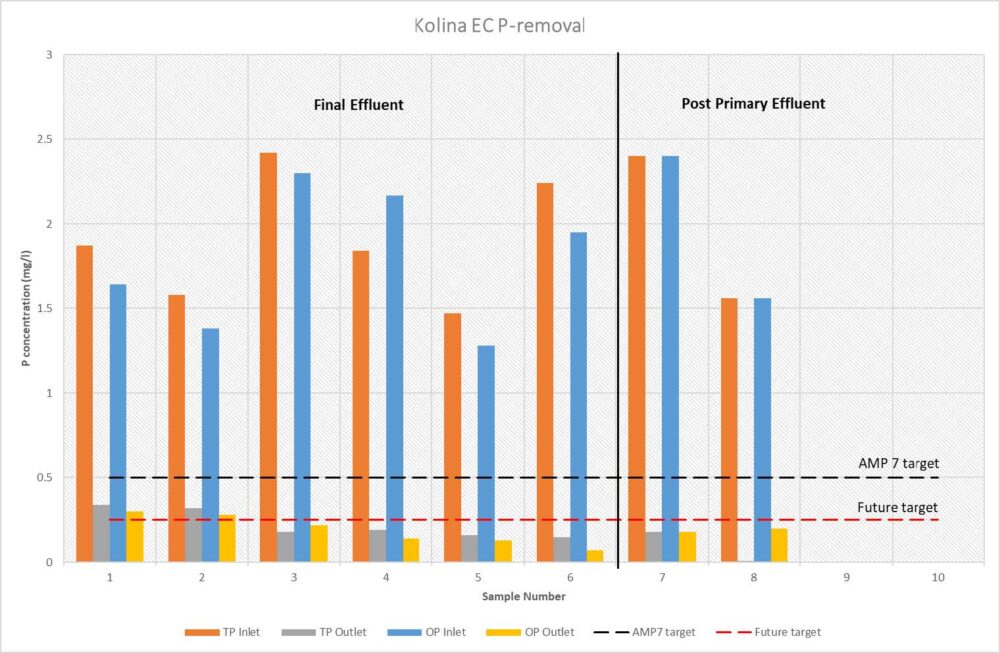

Phosphorus removal is crucial to maintain stringent environmental controls and regulations. ...

Read More

Treated wastewater from a UK fracking site for safe discharge to a local brook, saving the client...

Read More

Kolina partnered with a leading chemical decontamination company to treat the residual chemical...

Read More