Phosphorus Removal

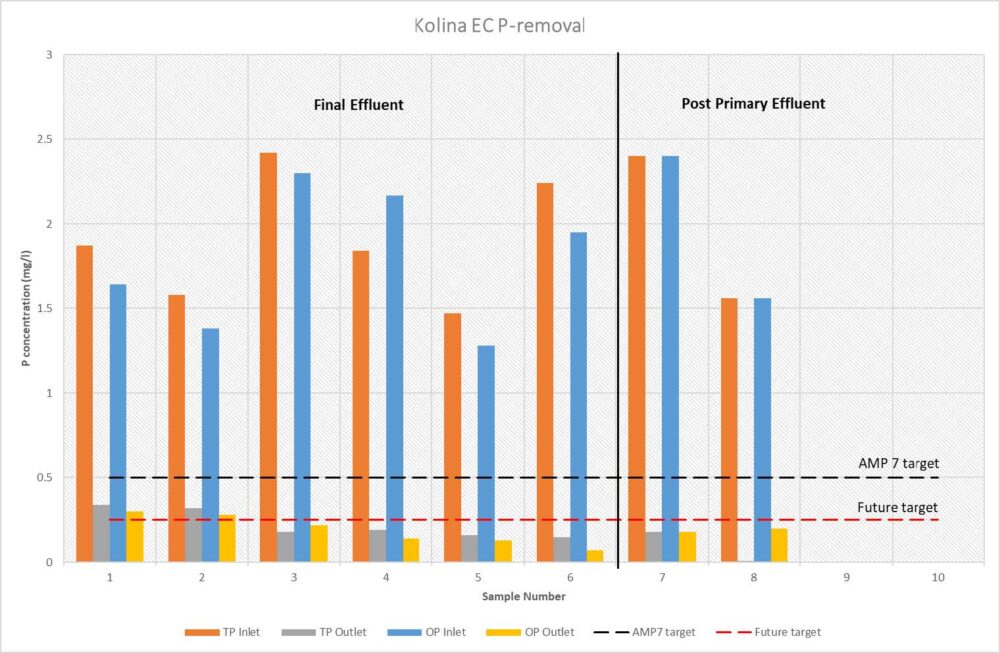

“Kolina's Phosphorus Removal plant conclusively removes both total and orthophosphate to below the current (AMP7) and future limits”

Interreg

Fracking Wastewater

“Eliminating the cost of removing 12 tankerloads of water daily was a huge saving and a great benefit to the environment. Kolina have helped immensely in our work with the Environment Authority.”

Project Engineer

Chemical De-comm

“Kolina's mobile, multi-stage treatment plant has allowed us to treat and safely discharge huge volumes of stored effluent at a fraction of the storage costs.”

Environmental Regulations Manager

Asian Food

“We now achieve consent levels and enjoy a 74% reduction in our effluent discharge cost, all thanks to Kolina's Electrocoagulation technology.”

Managing Director

On-shore Oil Exploration

“Kolina's technology has transformed our business. They provide top quality engineering support, excellent customer service and have help us meet all our environmental responsibilities.”

Programme and Performance Manager

Specialist cooked meat

“Following the installation's success at our initial site, Kolina now provide us with multi site waste water treatment solutions across the group.”

Group Network Director

Crisps and Snacks

“Kolina deliver a robust, sustainable solution to meet our needs. We're now discharge compliant and have made huge savings in waste disposal. ”

Planning and Engineering Manager

Condiment and sauce

“Great team offering knowledge, support and a smile. Such notable reductions and cost savings, we are now consulting on further group initiatives.”

Technical Lead

Master pie maker

“From enquiry to commissioning, the whole installation process was excellently organised. Kolina now partner with us to deliver wastewater treatment solutions across further group sites.

”

Operations Director